Quality Process Engineer

![[title]](https://pim.heraeus.com/images/HRD/HER_EB_Job-Ad-Header_US_EN_working_2375x950px.jpg) |

Summary

The Quality Engineer in ceramics manufacturing is responsible for ensuring product quality and compliance with industry standards, customer requirements, and regulatory guidelines. This role leads the Quality Inspection team, oversees quality control processes, and drives continuous improvement initiatives to enhance product reliability. Key responsibilities include supervising inspectors, establishing inspection protocols, analyzing production processes, conducting root cause analysis, and collaborating with cross-functional teams to resolve quality issues. Additionally, the position supports new product development with quality input and compliance checks.

Roles and Responsibilities

- Ensure Quality Assurance & Compliance by Developing, implementing, and maintaining quality control processes specific to ceramics manufacturing.

- Ensure compliance with industry standards, customer requirements, and regulatory guidelines.

- Lead Inspection team: Supervise and mentor quality inspectors, ensuring accurate inspection and testing of ceramic products.

- Establish inspection protocols and provide training to maintain consistency and reliability.

- Process Improvement: Analyze production processes to identify quality risks and implement corrective actions.

- Drive continuous improvement initiatives to enhance product reliability and reduce defects.

- Root Cause Analysis & Reporting: Investigate quality issues, perform root cause analysis, and implement preventive measures.

- Prepare and present quality reports to management and stakeholders.

- Collaboration: Work closely with production, engineering, and supply chain teams to resolve quality concerns.

- Support new product development initiatives with quality input and compliance checks.

- Plans and conducts the analysis, design, test, and/or integration to assure the quality of the assigned product or component

What is required for the role:

- Bachelor’s degree in Engineering, Quality Management, or a related technical field; Green Belt/Black Belt certification preferred.

- 3–5 years of manufacturing inspection experience (precision or materials-based products) with strong proficiency in measurement tools and digital/optical inspection systems.

- Ability to interpret blueprints, engineering drawings, and GD&T, with practical experience using SPC for data collection and analysis.

- Strong knowledge of quality and compliance standards, regulatory requirements, and structured quality methodologies.

- Prior experience in a lead or supervisory capacity over hourly employees, including task assignment, workflow coordination, and basic front-line people‑management responsibilities (timecards, attendance, foundational employment-law awareness).

- Excellent communication skills, attention to detail, and ability to collaborate effectively with production, engineering, and quality teams.

ReqID: 58862

-

Featured Jobs

Related jobs

- Quality Process Engineer Chandler, United States Quality Process Engineer

Related Content

-

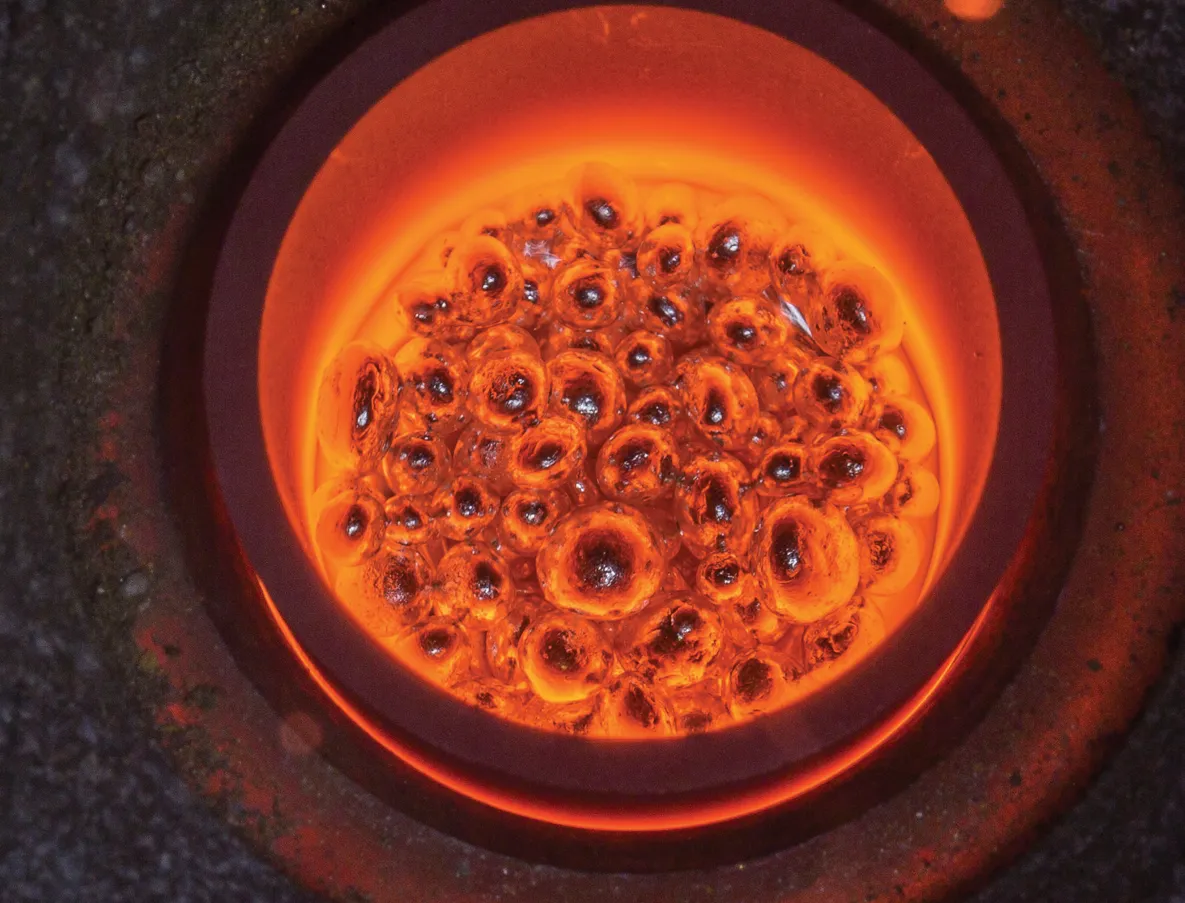

What we do

Our expertise revolves around materials.

-

What drives us

Innovations are part of our DNA.

-

Who we are

Our actions have been aimed at future generations since 1660.

-

Our Stories

-

Header Lorem Ipsum

Lorem ipsum dolor sit amet, consec tetur adipiscing ut enim ad minim veniam, quis nostrud

-

Careers at Heraeus: Great reasons to start your job

Discover your career opportunities at Heraeus. Learn why Heraeus is a secure and attractive employer for starting your career.

-

Work experience? Yes!

The Heraeus team wants to move forward. So do you. Discover our job opportunities!

-

Career entry? Yes!

You’re looking forward to the future. So are we. Start your journey with us!

-

Frequently asked questions

How do I apply for a job at Heraeus? Who can I contact with questions? We answer your frequently asked questions.

-

-

What Drives Our Work

What is it like to work at Heraeus? Who could answer that better than our employees?

-

-

EHS Gamification: Dr. Anja Teske, Head of EHS Governance and Performance

Have you ever told stories or opened the big game arena to really reach people? Anja has chosen exactly this path. Her training concept for greater safety in the workplace relies on experience rather than instruction. Read her story to find out why she is right on the money.

-

Who are you then: Dr. Martina Gieg, Chief Human Resources Officer & Member of Group Executive Leadership Team

Anyone who has wandered through the landscape of various companies in the consulting world will be familiar with this initial barrier of distance that must first be broken through. But is there another way? Find out how she cracked the code in Martina's story.

-

Silence or alarm: Dr. Anja Teske, Head of EHS Governance and Performance

Sometimes it takes the precision of a surgeon to communicate faulty working methods. The wrong tone of voice could create defensiveness. The right word, on the other hand, saves lives. Find out more from Anja about the art of communicating with sensitivity in our occupational safety department!

-

This certain moment: Dr. Martina Gieg, Chief Human Resources Officer & Member of Group Executive Leadership Team

Pling! Martina's plans for today? Perfectly timed. Everything crystal clear. And then that one moment when it becomes clear: everything is different than planned. How can a colorful mix of things become a productivity turbo? Read more!

-

Job and jogging? Every step counts: Arthur Charlet, Head of Heraeus Medical; Co-President HME

Can you hear that? It's the rhythm of your comfort zone. Pleasant, safe, but also frighteningly stationary - Arthur found this and turned his career path into his personal jogging route. Discover the amazing parallel between jogging shoes and paths to success in our story!

-

Click here for the sparring session: Arthur Charlet, Head of Heraeus Medical; Co-President HME

Jumping in at the deep end - most people are familiar with this moment. For Arthur, at least, it was a leap into a new job world with lightning-fast progress. Why sometimes the most uncomfortable moments hold the most valuable lessons - read the full story!

-

From zero to one hundred: Dr. Martina Gieg, Chief Human Resources Officer & Member of Group Executive Leadership Team

There are offices that are like blank slates. But don't be fooled, because a dynamic rhythm is already pulsating here. It is literally a green field with unimagined possibilities. Read what our Group People Officer has experienced on the playing field without pre-drawn lines!

-

Tough but lovely: Dr. Anja Teske, Head of EHS Governance and Performance

A near-accident. A statistic. Just a number on paper? Wrong. Behind every avoided accident are people who will be coming home from work tonight. Meet our audit manager Anja, who dares to take a different look!

-

Dent in the market: Arthur Charlet, Head of Heraeus Medical; Co-President HME

The engine of the automotive industry is sputtering. Arthur experienced this at our production sites at the time. Standing idle? Not an option. Only a gear change can catapult you forward and make the twist. Discover how a challenge gave rise to a completely new way of thinking.

-

-

-

-

-

-

-

-

-

-

Operations & Supply Chain at Heraeus Medical

Test description

-

-

From the city to the countryside: Nicole Kietzmann, Controller & Team Lead Controlling Services

“Wehrheim? Seriously!” After completing her dual studies, Nicole nevertheless decided to move to a location that many people first have to google. Why? Because sometimes great happiness lies in small things. Read on to find out what tipped the scales in Nicole's job decision.

-

Life is like a box of chocolates: Elke Berndl, Senior HR Manager

Some jobs are more than just a career move. They combine everything you can do and love. That's how it was for Elke when she became HR Manager at Heraeus Medical. Immerse yourself in her personal story, in which she explains why HR is close to her heart.

-

I'm off then: Nicole Kietzmann, Controller & Team Lead Controlling Services

From zero to a hundred? Sometimes things turn out differently than you think. Nicole takes on full responsibility for production controlling in a crash course. Join her on her challenge, which culminates in a completely new concept for standard cost accounting and a foundation that still stands today.

-

Bold ideas for the future : Elke Berndl, Senior HR Manager

How does knowledge stick? What makes teams truly future-proof? Elke knows the answers. Instead of dry training sessions, she has introduced learning journeys, future skills tools, and interactive onboarding programs. Discover how Elke has created new formats that help people grow.

-

From solo to symphony: Tony Bui, Junior Product & Project Manager

What began as a side job while studying medical technology turned into a surprising career opportunity for Tony. Read his story to find out what a small card note and his passion for music have to do with his rapid development.

-

A bold change of roles: Martina Humez, Manager Medical Training

A bold step backward and yet forward: after years in management, Martina returned to science. What looked like a risk to some turned out to be a win - for her, the company, and the customers. Read how a change of roles became a personal triple win.

-

Where are your children now: Martina Humez, Manager Medical Training

Between bone cement and children's laughter – Martina proves that career and family are not mutually exclusive. She shows how both can be combined and how skeptical questions can be confidently refuted. Discover how she follows her path with passion and courage.

-

When work changes lives: Trang Funke, Brand Manager

Some career paths start quietly - yet have the potential to make a big impact. Whether in the laboratory or in medical technology, Trang has always been driven by the desire to make a difference with her work. Find out how responsibility has a double impact on her.

-

The Power of Authenticity: Tim Bächle, Sales Consultant

From clinical consultant to sales professional: For Tim, the change was a real challenge. But instead of hiding behind sales clichés, he focused on what really matters. Find out how he landed his first big deal for PalaJet®!

-

Stay Strong: Katharina Apitius, Head of Sales EMEIR

That's exactly how it happened: as the only woman among the CEOs of large US companies – and on top of that, in a tense market situation. Katharina stood her ground and ultimately even became the spokesperson for the group. Find out how courage can change more than you think.

-

Do you know Peter: Katharina Apitius, Head of Sales EMEIR

Does the power of human connections last forever? Almost. A chance conversation in the Jordanian desert leads to a moving reunion. Find out how Katharina brought Professor Ahmed and Swiss surgeon Peter back together on a business trip.

-

My path as a woman to the executive suite: Katharina Apitius, Head of Sales EMEIR

Rising to international leadership in a male-dominated field? Women have always pursued their career paths, and they continue to do so today. Read how Eastern Europe and Russia became a springboard for Katharina. Learn what perseverance and support can achieve in her story.

-

Mobility Makers: Christian Haug, Team Leader Quality Control / Powder & Accessories

Whether at the gym or at his grandfather's house, Christian has seen firsthand how Heraeus Medical products positively change lives. Today, he supports his team as a team leader in the laboratory. Find out now how he ensures that bone cement is not only tested, but also helps people get moving again!

-

Five areas. Five worlds: Oliver Brück, Head of Systems Engineering

Do you know that feeling? At first, you only see differences – seemingly insurmountable clashes between different mindsets. Old hands versus young talent, introverts versus extroverts. Find out how Oliver put the puzzle together to create a team that shines with diversity - just click here!

-

How we simply built our office ourselves: Timo Mack, Head of Production

An empty floor, a dreary room - but Timo had a vision: to set up an office from scratch that would enable agile working. Read how sprints, retros, and genuine team power were used to create spaces that connect people.

-

Servant Leadership: Timo Mack, Head of Production

From the laboratory to the heart of life. Timo has turned his back on experimenting for the sake of it and is now working on something bigger: enabling millions of patients to live a pain-free and mobile life again. See how he brings his best team recipe to life!

-

-

Playing through pain: Thembela Kwini, Chemical Process Operator

When grief finds its way into the workplace, compassion and humanity often become the strongest sources of support. Discover how Thembela faced one of her saddest moments – and how she stood by her team with strength and empathy during a time of deep sorrow.

-

-

Daring to Start Over at 30? Absolutely: Yingchun "Karen" Guo, HR Manager, Heraeus (China) Investment, Shanghai

“I always admired those who could shape perspectives with their expertise – I just never imagined I could become one of them.” This realization sparked Karen’s journey from administration to a Project Coordinator at the Regional Center of Heraeus Greater China. Here’s how she got there.

-

Straight into a rocket launch and an Award as a Reward: Guifang "Karen" Wang, HR Manager C&B, Heraeus (China) Investment, Shanghai

Whether on the road or in a project, accelerating from zero to one hundred is a special feeling. It takes courage, stamina, and skill. These were exactly the strengths Karen brought into the large project team that developed the Competence Development House at Heraeus Electronics. This is the story of how her workplace became a space where visions can turn into reality.

-

Mission Impossible? Not at Heraeus: Rui "Angie" Wang, Business Application Consultant, Heraeus (China) Investment Co, Shanghai

Sometimes, it’s the quiet moments that matter the most. An email, a word of praise, and the realization that something great can emerge from a seemingly impossible task. Discover how “Angie” mastered a real project challenge – both professionally and personally.